GE Bracket Challenge

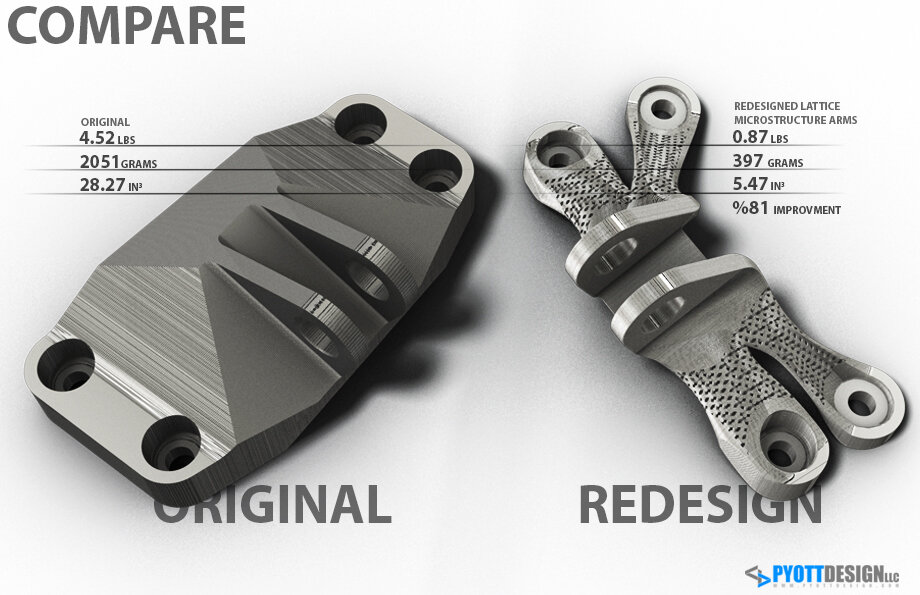

GE offered up a design and engineering challenge through GrabCAD. The competition was to take a supplied bracket and redesign it to be built in 3D printed SLS titanium in as light a weight as possible while still maintaining minimum strength characteristics.

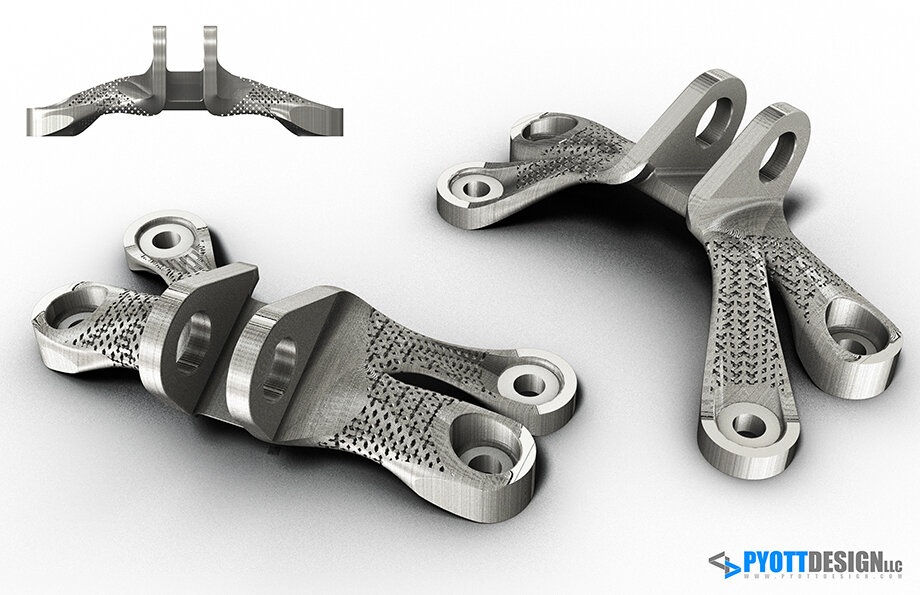

The underlying goal was to demonstrate the design possibilities that open up when using advanced manufacturing.

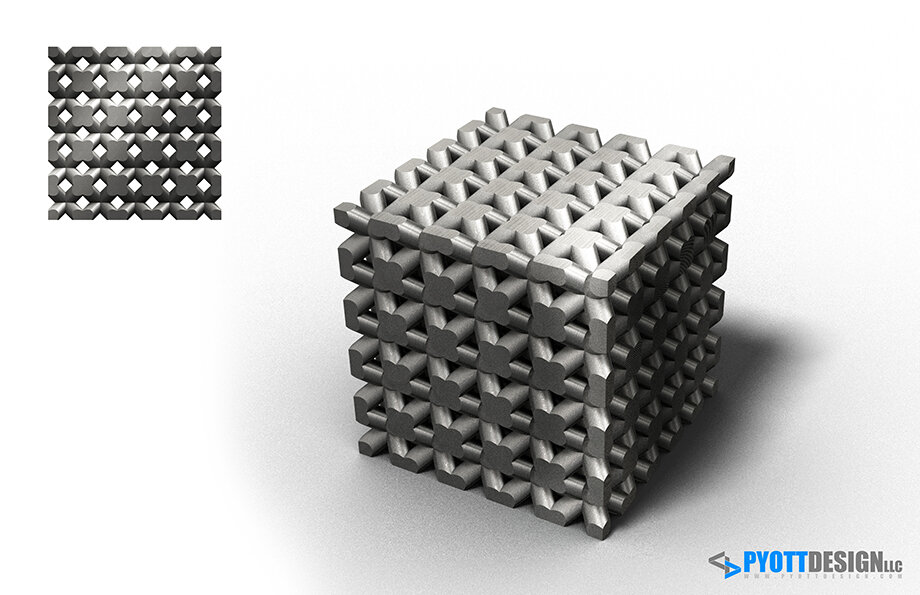

My solution used a solid optimized bracket developed out of FEA load simulations run in Solidworks. After that a micro lattice structure was built into the bracket arms, further light-weighting the part. I was able to get an +80% decrease in weight in the new model.