Kayak

This was my first try at making a skin on frame kayak! I wanted a light weight design that could hold enough for an overnight camping trip.

This design is a heavily modified version of a design found in "Fuselage Frame Boats - A Guide to Building Skin Kayaks and Canoes" by Jeff Horton. Aside from hull changes, this design uses a non-conventional overlapping lower skin design for a cleaner look. The build was pretty painless although the frame was hand cut then cleaned up with a hand router which was pretty rough (think I will go CNC next time).

Solidworks was used for the hull design and rib cutting templates were printed on 11” x 17” paper. All the ribs are cut out of marine grade plywood and the stringers are fir.

There is no glue or hardware used on connecting the ribs to the stringers. Instead everything is tied together using synthetic sinew. The amount of tension you can get on the lines is pretty crazy and you can see it biting into the birch and plywood.

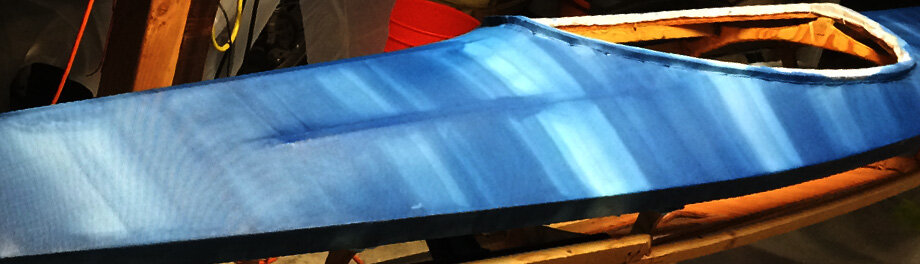

Polyester fabric was sewn to the frame and a heat gun was used to shrink it in place. Polyurethane sealant (usually used for concrete floors) was applied to the 8 oz fabric to get it water tight. Fiberglass rods and heat bent ABS plastic rod front/rears are connected with stainless steal tube to create a top hoop.