Another in the series of automated custom product generation, this project brief was to create custom 3D printed teeth whitening trays from patient scan data.

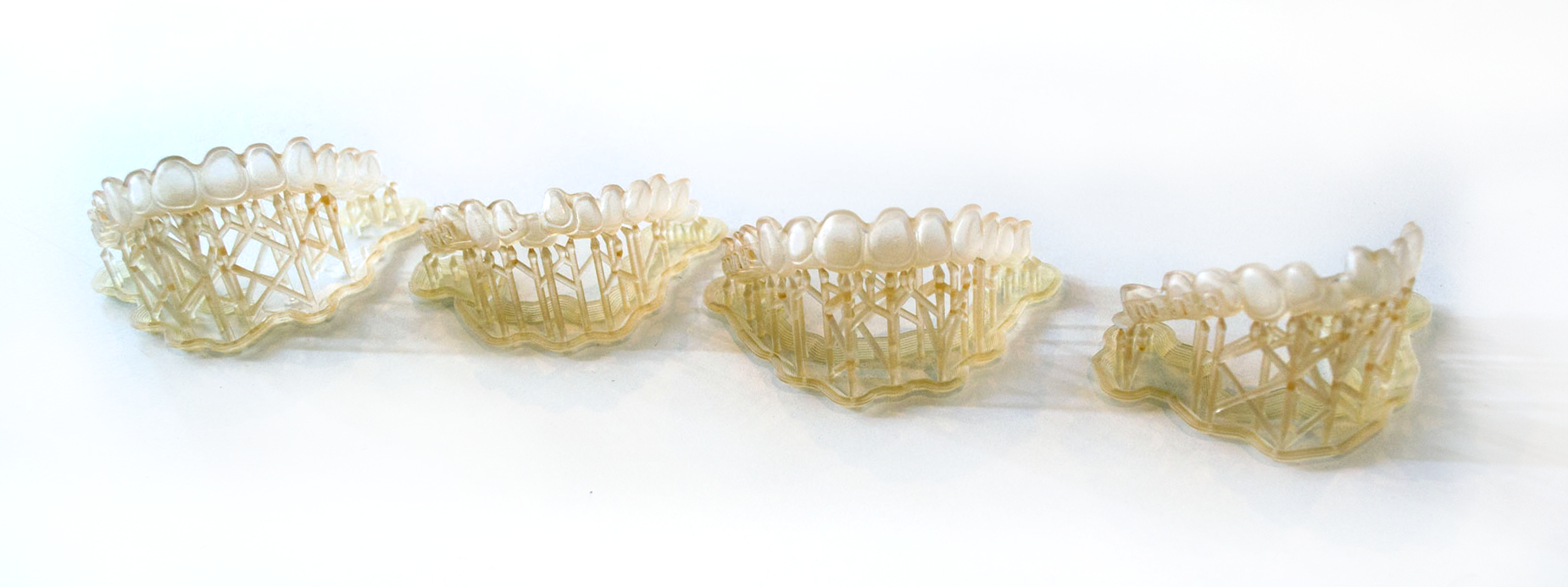

Currently custom teeth whitening trays are made by scanning a patients upper and lower teeth, 3D printing out a physical model then painting caps on the front of each individual tooth. The model can then be used to vacuum form plastic trays which are then manually trimmed down, resulting in the final product. Needless to say, this is a process that requires a significant amount of time and manual labor to create a finished whitening tray.

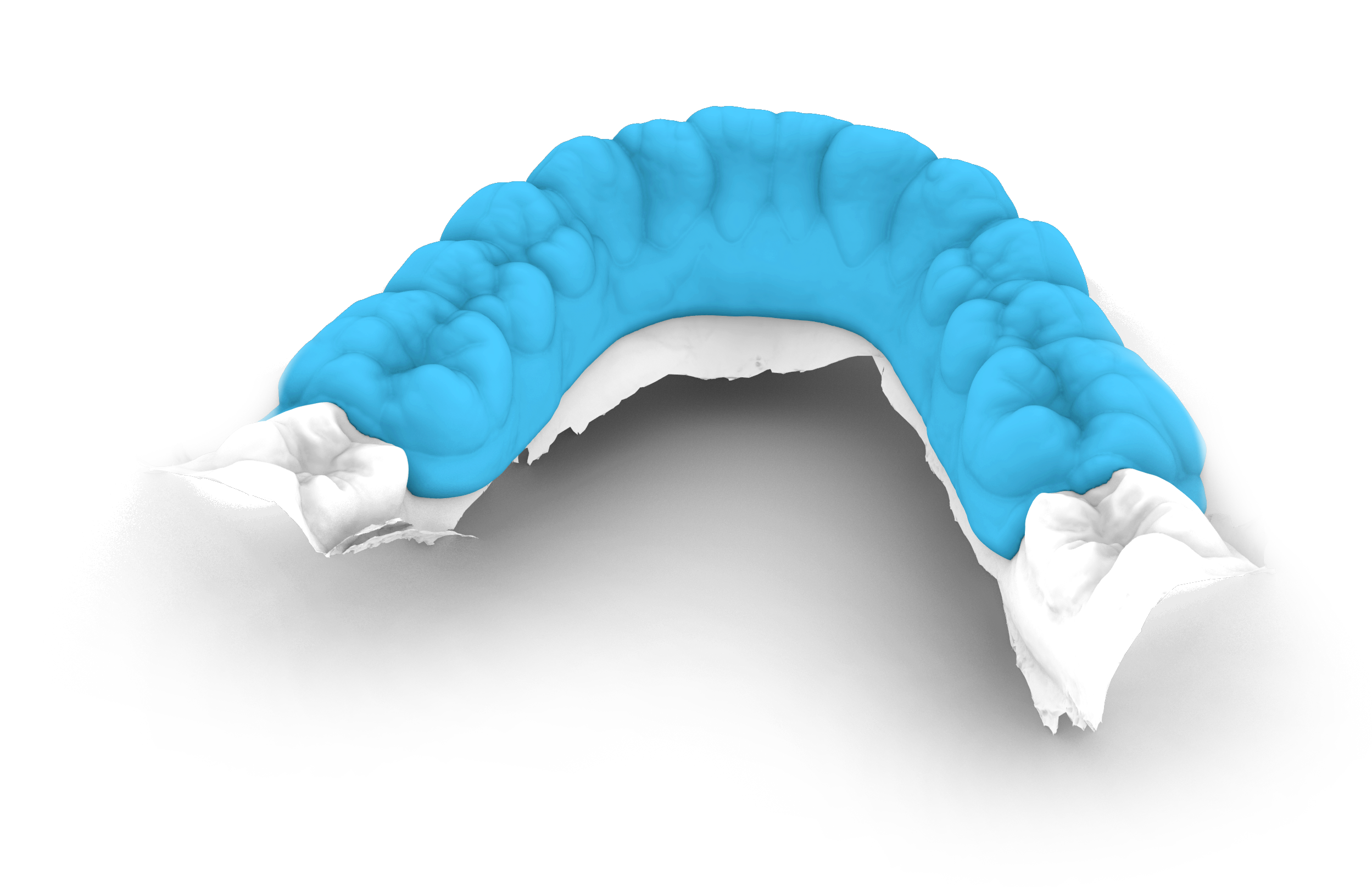

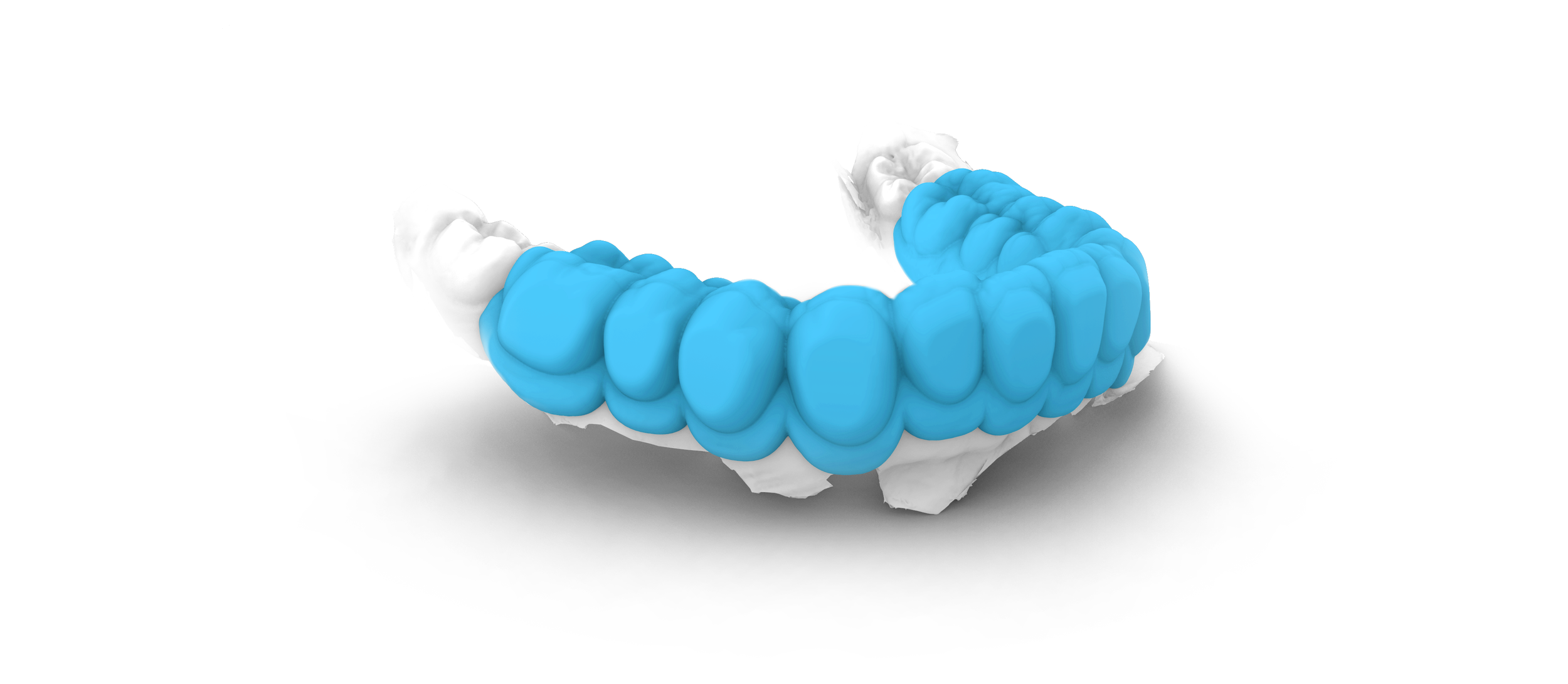

We created a system that could individually identify teeth from input scan data, build up reservoirs for the whitening paste and direct print the finished tray with no additional steps.

A GUI was created to control various aspects of the print. Additional features such as the ability to skip teeth that were not needed and a unique serial number being debossed onto every model were added to make the system even more powerful.